5. Repair of pipe lining

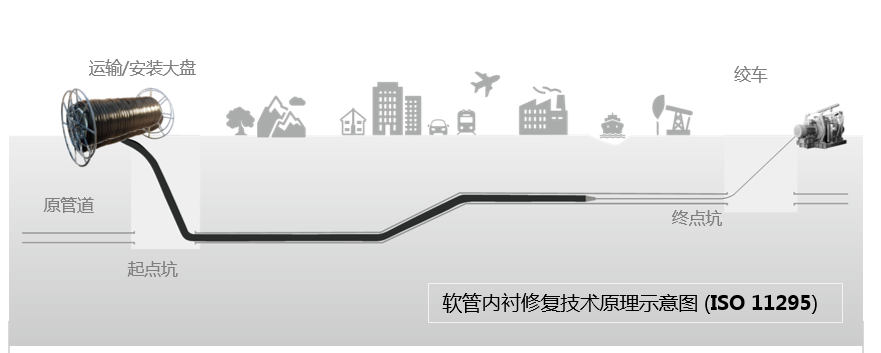

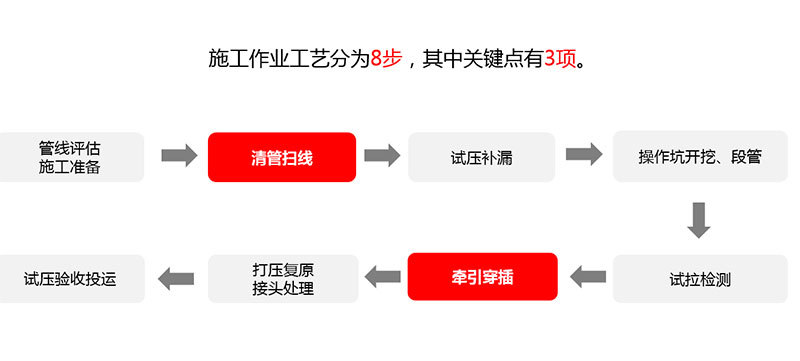

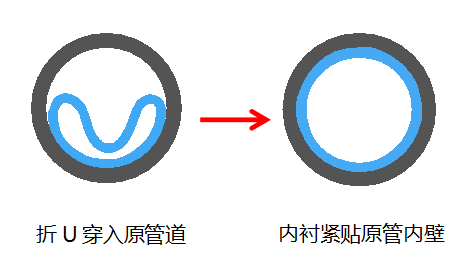

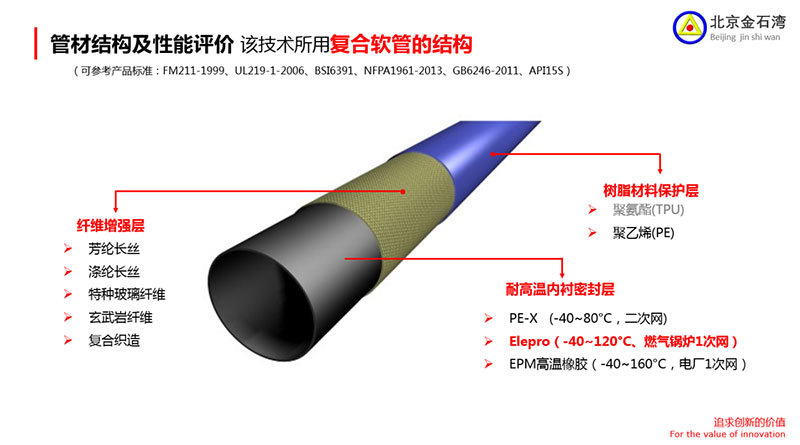

The whole process of pipeline lining repair is composite hose lining (Inserted, IH) trenchless repair technology, which is to line a high-pressure continuous composite hose into the original metal pipeline to form a "pipe-in-pipe" composite structure. Under working conditions, the hose is close to the metal pipe.

Features and applicability:

Corrosion resistance-Non-metallic corrosion resistance;

Self-pressure-Bare tube pressure 1.6 MPa, blasting pressure 4.8MPa;

construction fast-Construction speed 300-400 m/h;

Over elbow-One pass through R5D elbow (90 °);

wide caliber-Repair the pipeline DN50-DN1200;

Distance long-- According to the needs of the project, the maximum distance of one construction straight line is 5km.

Main applications: oil field high-pressure corrosion pipeline repair, municipal water supply pipeline renewal, thermal pipeline renewal, industrial and mining water supply pipeline repair, gas pipeline repair or boost transformation.

Previous Page

Next Page

Previous Page

Next Page

Contact Information

E-mail:

Mobile:

Address:

Beijing Changping District Beijing Jinshiwan Pipeline Technology Co., Ltd.

COPYRIGHT©2024 Beijing Jinshiwan Pipeline Technology Co., Ltd.